-

CompanyCapability

Technical center

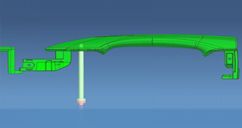

Engineering Team

Project management

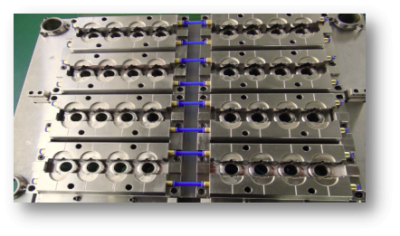

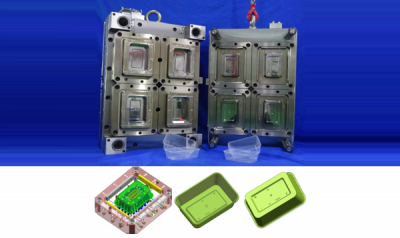

Manufacturing

Tooling machines

Trial machines

-

ProductAutomotive

Health care

Medical

Consumer

-

Quality

-

Contact us

Jinxia Hexi Industrial Zone,Chang'an,Dongguan,Guangdong,China

+86-769-38807000

Quality control

Quality Control

Wellmei is running ISO9001 quality management system combine with TPS Lean Production system to ensure our mold quality. We are aiming “Quality First” to be our everlasting topic, “Customer satisfaction” is our pursue for leading market.

Quality Control center

Wellmei owns an experienced team for quality control, applying ourselves to provide customers with best quality mold and delivery time.

We are running Incoming quality control (IQC), In process quality control (IPQC) &

Quality assurance (QA)

Quality Control Flow chart

1. Mold frame checking

2. Steel checking

3. Mold component checking

4. Electrode checking

5. Mold checking before assemble

6. Part full dimension checking (FAI, CPK report)

7. Mold checking before delivery

|

MOLD & STEEL DIMENSION MEASUREMENT EQUIPMENTS |

|||||

|

Coordinate Measuring Machining (CMM) |

MACHINE NAME |

BRAND NAME |

MODEL |

MACHINE SIZE(mm) |

QTY. |

|

Full automatic CMM |

Carl.Zessis CONTURA G2 |

3D |

700*1000*600 |

1 |

|

|

Full automatic CMM |

MITUTOYO C574 |

3D |

510*710*455 |

1 |

|

|

CMM(Rotable head) |

Mitutoyo BHV507 |

3D |

700*500*400 |

1 |

|

|

CMM |

Mitutoyo BHV507 |

3D |

700*500*400 |

1 |

|

|

Toolmaker's Microscope |

MITUTOYO MF-A1730H |

2D |

300*200*250 |

3 |

|

|

Microscope |

Automotive CMM (3D) |

Germany RODERS |

CONTURA G2 7/10/6 |

700*1000*600 |

1 |

|

Microscope |

Japan Nikon |

VMA-2520 |

250*200*200 |

1 |

|

|

Hight Gauge |

Japan Mitsutoyo |

518-341DC |

600mm |

1 |

|

|

Hardness Testing Machine |

Lianer

|

HR-150A |

1 |

||

|

Raster display mapper |

Raster display mapper |

ECOM-111 |

P |

350*200*100 |

1 |

|

Raster display mapper |

EV-3020 |

P |

300*200*200 |

2 |

|

|

Pneumatic height gages |

MITUTOYO LH-600 |

2D |

600mm |

2 |

|

|

Total: 5 CMMs,3 Toolmaker's Microscopes,4Raster display mappers,4 Pneumatic height gages |

|||||